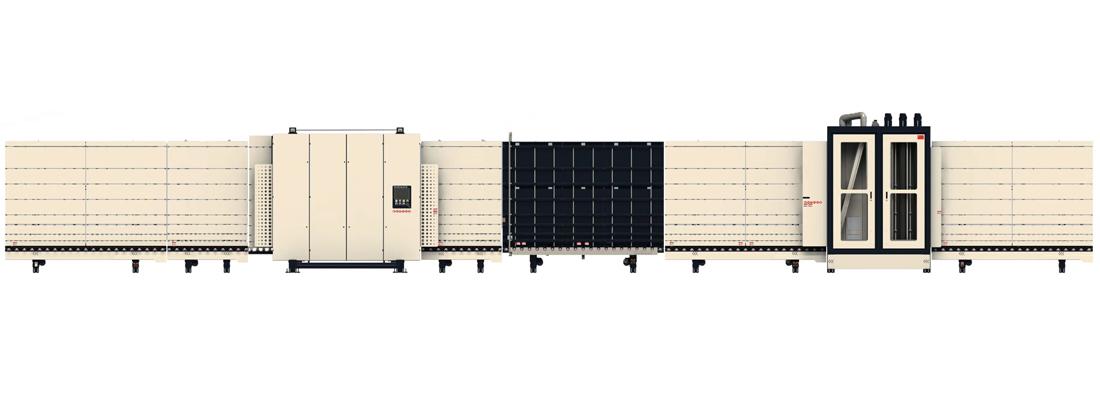

High-speed Intelligent Production Line

IL22-A3-7S All new high speed automatic insulating glass production line

Views:

Product Description

system components

Transfer segment:

Automatically identify the Low-E coated film surface;

The transfer wheel has no key connection to ensure the longest service life;

The height and length of the glass are automatically recognized and automatically switched.

Glass washing and drying machine:

Continuously wash and dry glass of various sizes and thicknesses;

Three pairs of brushes, high quality brush independent drive, steering optional;

Chainless brush and glass transfer, transmission axis synchronization drive;

Independent washing area to ensure the quality of cleaning;

Small glass high-speed washing function;

Fan active noise reduction system.

Aluminum frame positioning installation and inspection machine:

Deep detection glass system, soft light source, effective high-speed detection of glass quality;

Adaptive glass thickness aluminum frame mounting system;

Glass positioning control glue depth is adjustable;

Glass pause function;

The operator place frame according to indicator color;

The whole machine one-button start function.

Combine and plate press machine:

Automatic splicing of double glass hollow glass and triple glass hollow glass;

Can produce three or four sides, large and small pieces (optional);

Processing different sizes and thicknesses of glass in any order;

Continuous combine;

Board floating adjustable system;

Glass pressing adopts servo motor and lead screw for digital control.

Transfer segment:

Automatically identify the Low-E coated film surface;

The transfer wheel has no key connection to ensure the longest service life;

The height and length of the glass are automatically recognized and automatically switched.

Glass washing and drying machine:

Continuously wash and dry glass of various sizes and thicknesses;

Three pairs of brushes, high quality brush independent drive, steering optional;

Chainless brush and glass transfer, transmission axis synchronization drive;

Independent washing area to ensure the quality of cleaning;

Small glass high-speed washing function;

Fan active noise reduction system.

Aluminum frame positioning installation and inspection machine:

Deep detection glass system, soft light source, effective high-speed detection of glass quality;

Adaptive glass thickness aluminum frame mounting system;

Glass positioning control glue depth is adjustable;

Glass pause function;

The operator place frame according to indicator color;

The whole machine one-button start function.

Combine and plate press machine:

Automatic splicing of double glass hollow glass and triple glass hollow glass;

Can produce three or four sides, large and small pieces (optional);

Processing different sizes and thicknesses of glass in any order;

Continuous combine;

Board floating adjustable system;

Glass pressing adopts servo motor and lead screw for digital control.

Technical Parameters

Processing height: 2200mm

Processing size: Minimum: 220 × 380mm

Maximum: 2200 × 3000mm

Secondary lamination: 2200 × 4600mm (automatic identification of glass length, automatic secondary lamination)

Thickness of insulating glass: 12-60mm

Interval width: 6-24mm

Thickness of cleaning single piece: 3-16mm

Cleaning speed: 0-17m / min

Transmission speed: 0-48m / min

Working height: 480 ± 50mm

Tilt angle: 6 °

Gluing depth: 0-20mm

Working direction: right- left / left- right

Lamination mode: servo screw lamination

Overall dimension: 2200mm × 2100m × 3500mm

Processing size: Minimum: 220 × 380mm

Maximum: 2200 × 3000mm

Secondary lamination: 2200 × 4600mm (automatic identification of glass length, automatic secondary lamination)

Thickness of insulating glass: 12-60mm

Interval width: 6-24mm

Thickness of cleaning single piece: 3-16mm

Cleaning speed: 0-17m / min

Transmission speed: 0-48m / min

Working height: 480 ± 50mm

Tilt angle: 6 °

Gluing depth: 0-20mm

Working direction: right- left / left- right

Lamination mode: servo screw lamination

Overall dimension: 2200mm × 2100m × 3500mm

Related Products